3D cameras

Integrated processing

Industrial housing

Built-in IO

3D vision cameras: advanced image processing

A 3D vision camera offers an innovative solution for inspection and measurement applications. Using technologies such as laser profiling, stereo vision, or structured light, a 3D vision camera captures three-dimensional information. With the help of software, this data is then converted into a complete 3D image.

This technology is ideal for applications where precision, depth perception, and volume measurement are essential. It is the preferred choice when a 2D camera cannot provide sufficient information for inspection.

How does a 3D vision camera work?

A 3D vision camera records depth information using different technologies:

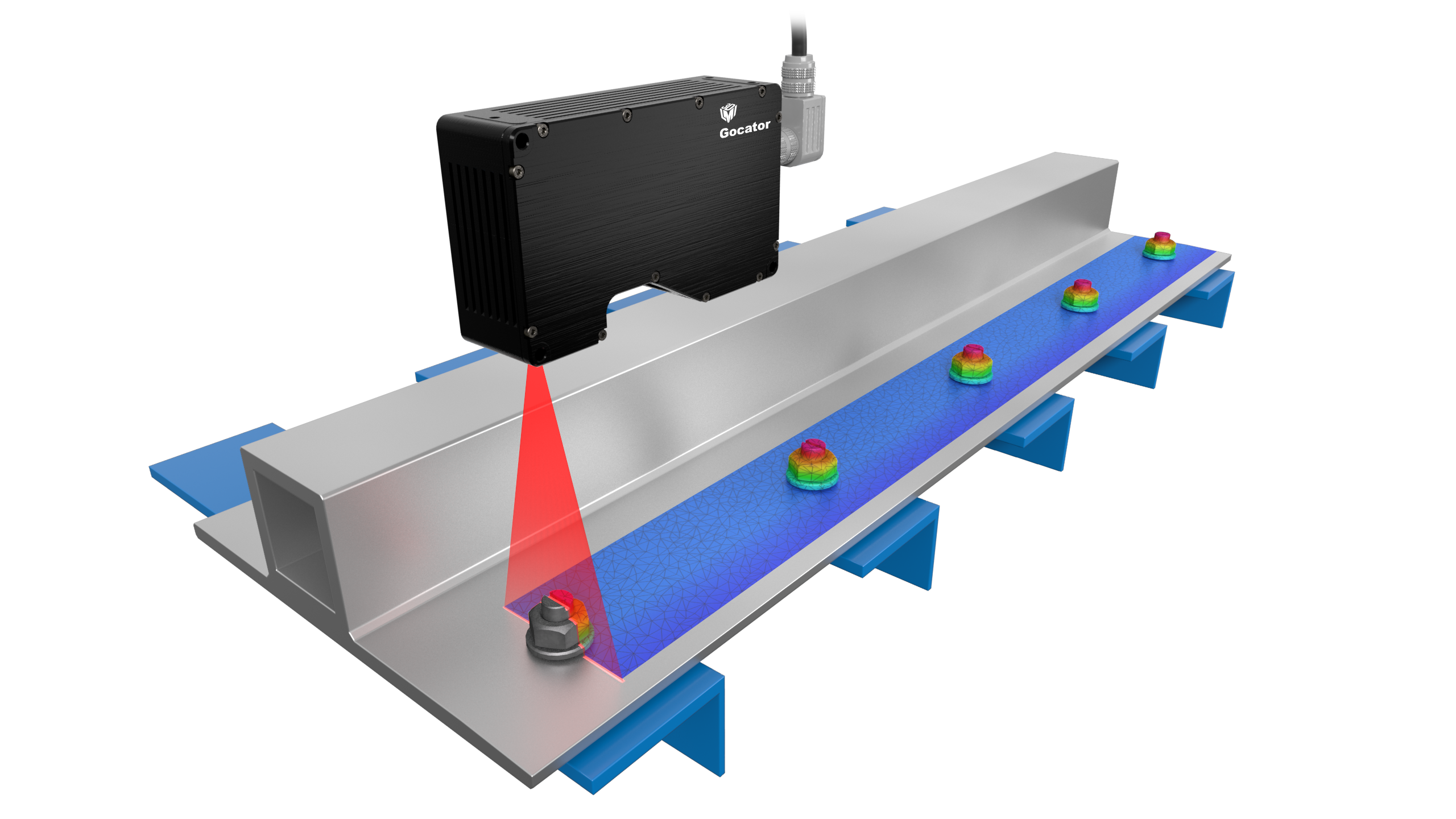

- Laser profiling – a laser beam scans the object, and the deformation of the light pattern is used to calculate height information.

- Stereo vision – two cameras work together to create a 3D image by analyzing differences in perspective.

- Structured light – a pattern is projected onto the object, and the distortions provide data about its 3D structure.

There are smart cameras available that can generate 3D images. Thanks to a built-in processor, the images can be immediately processed and analysed. The result can then be immediately transmitted. Considering that these cameras still have a very limited capacity, our preference is for using the raw images. The 3D information is then calculated on a host or a local computer.

Applications of 3D vision cameras

3D vision cameras are ideal for precision inspections, robotics, and volume analysis in automated production lines. This technology is widely used across different industries:

- Food industry – Measuring the volume of products such as potatoes, cheese, and meat. Learn more about product quality control in the food sector.

- Packaging industry – Detecting height variations and defects in packaging. Learn more about packaging inspection.

- Automotive and metalworking – Inspecting welded joints and analyzing surfaces. Learn more about product quality control in the non-food sector.

- Robotics and automation – Enabling accurate positioning and object recognition for automated systems.

Would you like to know how a 3D vision camera could fit into your production process? Our specialists will be happy to help.

Gocator 3D sensors by LMI

We employ Gocator 3D sensors by LMI. These sensors are efficient in design and offer consistent high performance. The Gocator is easy to integrate in existing inspection systems and is suitable for a wide range of critical inspection applications.

3D cameras: advice and support

Which Gocator sensor best suits your needs, depends on the type of inspection, the required image quality and the physical conditions around the object and the camera. As a dealer for LMI products, we can always offer the most suitable sensor.

Our engineers have extensive knowledge of our products and experience with various combinations and applications. We can also organise a demo of various products and systems for you. With custom advice, we ensure that the 3D camera delivers the required results. If, after purchase, you encounter issues in practice, our support department will find a suitable solution.

Want to know more about 3D vision cameras?

Would you like to know more about 3D cameras and Gocator sensors, their application and our range? Please contact us. We would be only too pleased to supply additional information.

Tip! Have you opted for a 3D camera? Ensure you have an appropriate lens, housing and lighting. Together with the right IT support, such as vision controllers and frame grabbers, you complete your machine vision system to achieve an optimum result.

Components